Corrosion is ‘the enemy’ when it comes to preventing lighting failure that can result in trucking downtime and the need for lighting repairs. And, when it comes to reducing the likelihood of truck and trailer wire harness or truck connector corrosion, it is the quality and material of the connectors that can keep fleets moving and roadways safer.

Here, we will look at 3 Peterson light and harness connector styles that can help fleet managers avoid lighting system CSA violations and maintenance crews prevent unexpected roadside failures and expensive maintenance issues that can all result from moisture intrusion and corrosion on trailer lights.

A Closer Look At Connector Design

While truck lighting harness connectors seem like extremely simple electromechanical devices, the engineering and design quality of these components are directly related to the life cycle and environmental ruggedness of a trailer’s lighting system. High-integrity lighting connectors depend on the following:

-

- Sealed housing to protect the internal components from external factors such as moisture, dust, oil, and grease

- Terminal fit tolerance that ensures a tight and proper connection for good electrical contact and current flow

- Metal terminal material selection to prevent dissimilar metal corrosion and/or corrosion due to environmental factors such as salt and moisture

- Non-conductive insert to separate the conductive contacts and maintain clearance, usually made from a plastic or rubber/silicone material

Even with these design principles built into the trailer light connector, the use of a silicone-based dielectric grease or spray can add even more protection against trailer light failure due to corrosion.

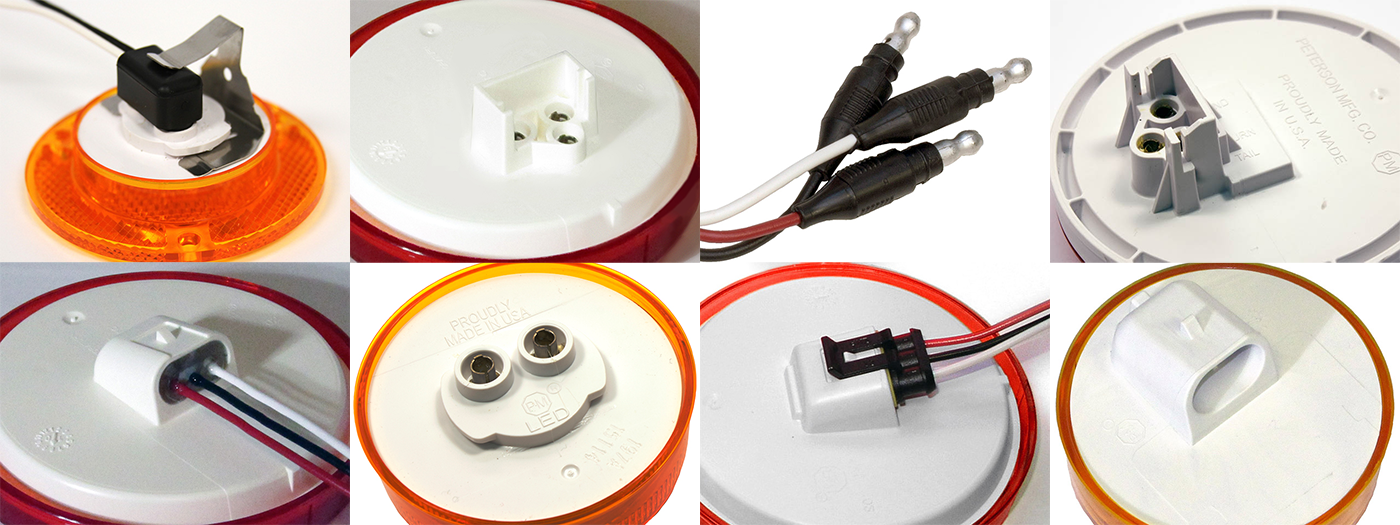

3 Styles of Connectors for Truck and Trailer Lights

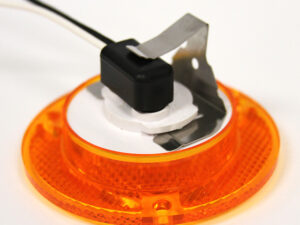

The industry standard is a good connector

For mild climates and light-duty trucking routes, the Peterson Industry Standard PL3 and PL10 are both low-cost solutions that provide basic corrosion protection due to moisture. The PL3 and PL10 are industry standard connectors that feature insert molded receptacles to fit a wide variety of applications. For an extra secure connection, the PL10 receptacles can accept an optional steel retaining clip, which keeps the plug firmly seated in the receptacle, while the standard PL3 plug features integral locking tabs to keep the PL3 plug firmly seated in the receptacle.

A high-quality dielectric grease should be used on both the Peterson PL3 and PL10 to protect the connections from corrosion due to moisture, salt, or chemicals.

|

|

|

|

A better connector for better environmental sealing

A better quality trailer light, wire harness, and light connector will have a longer service life and will be more dependable in climates where wet weather may be a factor. Peterson offers a better hardwired connection with .180 inch bullet connectors that adds more strength and better conductivity to the entire lighting system.

Bullet connector terminals are tin plated for maximum corrosion prevention and feature the exclusive Peterson’s Maxi-Seal Integrated moisture barrier. When paired with our proprietary harness components like the specially-designed detent ring, you get a positive seating and the best environmental seal available. While quality bullet connectors are a step up, Peterson’s bullet connectors are even better than those of other lighting suppliers—a whole lot better.

|

|

The best connector for unsurpassed moisture resistance

If your trucking logistics include coastal areas that feature salt water, northern US territories that feature salted roads during the winter, along with the many highways where heavy rain, sleet, and snow contribute to corrosion due to moisture infiltrating trailer light connections, then choose the best connector manufactured by Peterson, the silicone-sealed AMP-style plug connectors.

These 2-conductor receptacles are commonly used on trailers with 2″ and 2.5″ diameter round PM LED clearance/marker lights. The Amp plug connectors create the best environmental seal between the receptacle and the lighting circuit board to prevent blown lights due to moisture. Also available in the Amp plug style is a 3-conductor receptacle which is commonly used for rear Stop/Turn/Tail lights, mid-turn lights, and other lights with high and low intensity functions.

|

|

Visit Peterson online to learn more about our vehicle safety lighting and wiring harness solutions.

Peterson Manufacturing Company

Founded in 1945, Peterson Manufacturing Company is a world-leading innovator in the design, engineering and manufacturing of a complete line of commercial vehicle/trailer safety lighting and harness systems. With headquarters in the greater Kansas City area, Peterson is a privately held company. An ISO 9001:2015 certified company, Peterson Manufacturing is a key subsidiary of Peterson Corporation, five highly specialized companies and nearly 700 associates working in global transportation-related industries. For more information, visit PMLights.com.