|

|

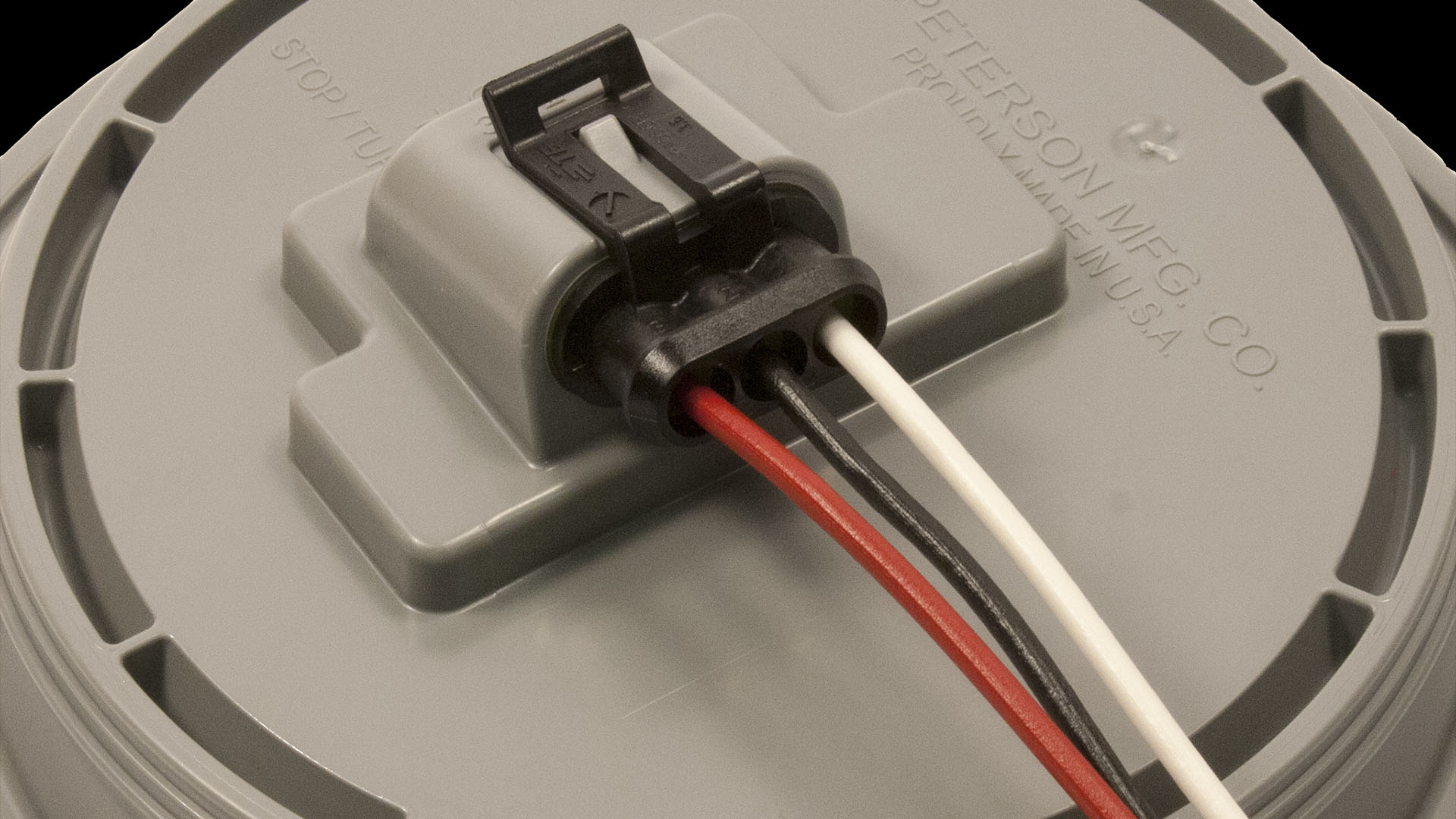

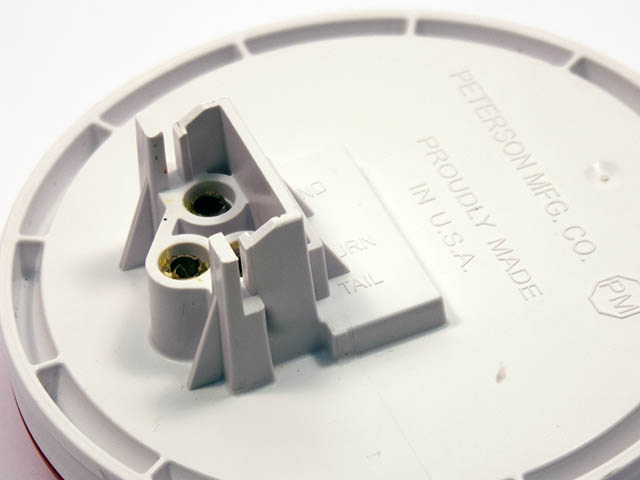

BEST CONNECTION:

AMP-COMPATIBLE INTEGRATED RECEPTACLE

Silicone-sealed AMP-style plugs are unsurpassed at fighting moisture intrusion and corrosion between the light and the harness. Peterson’s superior Insert-Molded manufacturing technology creates the highest quality environmental seal between the receptacle and the circuit board. 3-conductor receptacles are used on rear Stop/Turn/Tail lights, mid-turn lights, and other lights with high and low intensity functions. Two-conductor receptacles are common on 2″ and 2.5″ diameter round PM LED clearance/marker lights.

Never apply grease to silicone-sealed plugs and receptacles.

|

|

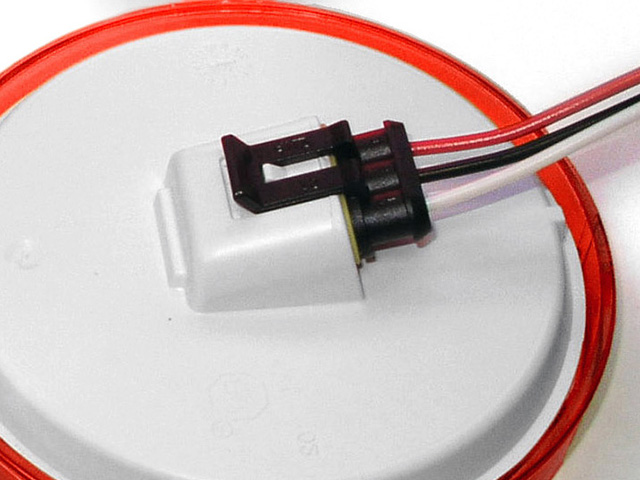

BETTER / BEST CONNECTION:

HARDWIRED WITH .180 BULLETS

Insert-Molded hardwired leads are used throughout the Peterson LED product line. These leads may be partially stripped for easy splicing, but are often equipped with industry-standard .180 bullet plugs. Our plugs feature PM / Maxi-Seal’s exclusive Integrated Moisture Barrier. When paired with Maxi-Seal harness components, our exclusive detent ring provides positive seating and the best environmental seal available.

High-quality dielectric grease should be used to protect .180 bullet connections.

|

|

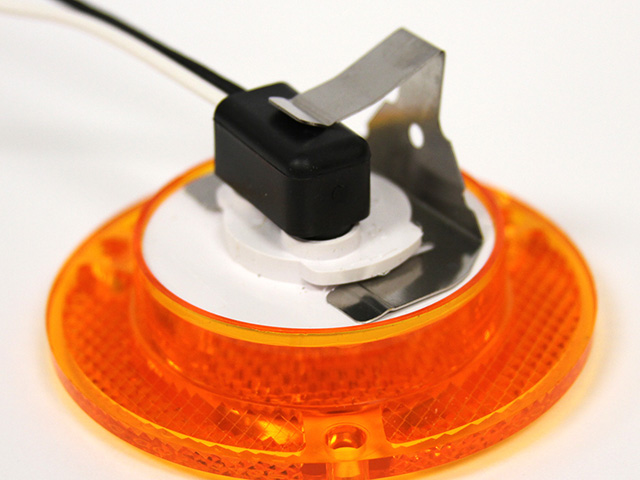

INDUSTRY STANDARD: PL10

Many Insert-Molded Peterson LED clearance/marker lights feature an integrated industry-standard PL10 receptacle. These lights fit a wide variety of applications at low cost with basic corrosion protection. In order to enhance the performance of the standard PL10 plug, many Peterson PL10 receptacles can accept an optional steel retaining clip, which keeps the plug firmly seated in the receptacle.

High-quality dielectric grease should be used to protect PL10 connections.

|

|

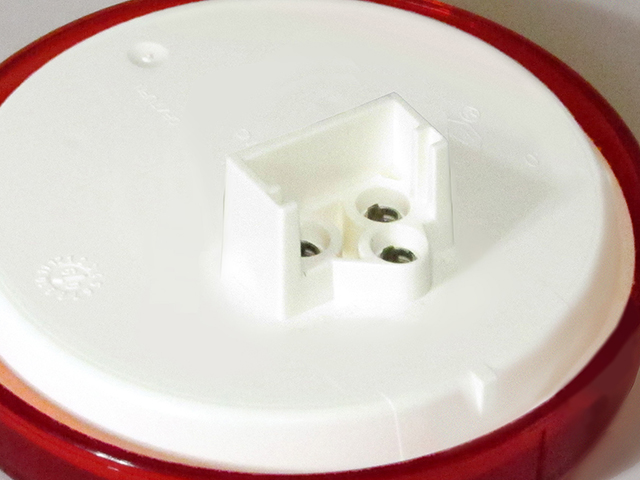

INDUSTRY STANDARD: PL3

Many Insert-Molded Peterson LED Stop/Turn/Tail lights, mid-turn lights, and other lights with high and low intensity functions have an industry-standard PL3 receptacle built right into the housing of the light. These lights fit a wide variety of applications at low cost with basic corrosion protection. In order to enhance the performance of the standard PL3 plug, some harsh environment Peterson lights have integral locking tabs to keep the PL3 plug firmly seated in the receptacle.

High-quality dielectric grease should be used to protect PL3 connections.

Our team of factory customer service professionals are always ready to help you with any other technical questions or information not listed here on our website.

If you have any questions, please contact us.