SAE Lighting

SAE Backup Alarms

SAE Strobes

Wire Gauges

INTERNATIONAL IP (Ingress Protection)

SAE LIGHTING IDENTIFICATION CODES & STANDARDS

| A | Reflex reflectors |

| A2 | Wide angle reflex reflectors |

| C | Motorcycle auxiliary front lamps |

| D | Motorcycle and motor-driven cycle turn signal lamps |

| E | Side turn signal lamps – vehicles 12 m or more in length |

| E2 | Side turn signal lamps – vehicles less than 12 m in length |

| F | Front fog lamps |

| F2 | Fog tail lamps |

| G | Truck cargo lamps |

| H | Sealed beam headlamps |

| HG | Discharge forward lighting headlamps |

| HH | Sealed beam headlamp housings |

| HR | Replaceable bulb headlamps |

| I | Turn signal lamps |

| I3 | Turn signal lamps spaced from 75 mm to less than 100 mm from headlamp |

| I4 | Turn signal lamps spaced from 60 mm to less than 75 mm from headlamp |

| I5 | Turn signal lamps spaced less than 60 mm from headlamp |

| I6 | Rear mounted turn signal lamps and front mounted turn signal lamps mounted 100 mm or more from the headlamp, for use on vehicles 2032 mm or more in overall width |

| I7 | Front mounted turn signal lamps mounted less than 100 mm from the headlamp, for use on vehicles 2032 mm or more in overall width |

| K | Front cornering lamps |

| K2 | Rear cornering lamps |

| L | License plate lamps |

| M | Motorcycle and motor-driven cycle headlamps – motorcycle type |

| N | Motorcycle and motor-driven cycle headlamps – motor-driven cycle type |

| O | Spot lamps |

| P | Parking lamps |

| P2 | Clearance, side marker and identification lamps |

| P3 | Clearance, side marker and identification lamps for use on vehicles 2032 mm or more in overall width |

| PC | Combination clearance and side marker lamps |

| PC2 | Combination clearance and side marker lamps for vehicles 2032 mm or more in overall width |

| Q | Turn signal operating units‚ Class A |

| QB | Turn signal operating units‚ Class B |

| QC | Vehicular hazard warning signal operating unit |

| R | Backup lamps |

| S | Stop lamps |

| S2 | Stop lamps for use on vehicles 2032 mm or more in overall width |

| T | Tail lamps (rear position lamps) |

| T2 | Tail lamps (rear position lamps) for use on vehicles 2032 mm or more in overall width |

| U | Supplemental high-mounted stop and turn lamps |

| U2 | Supplemental high-mounted stop and turn lamps for use on vehicles 2032 mm or more in overall width |

| U3 | Center high-mounted stop lamps for passenger cars, light trucks and MPVs |

| W | Warning lamps for emergency, maintenance and service vehicles |

| W2 | Warning lamps for school buses |

| W3 | 360-degree emergency warning lamps |

| W4 | Emergency warning devices |

| W5-1 | 360-degree gaseous discharge lamps‚ Class 1 |

| W5-2 | 360-degree gaseous discharge lamps‚ Class 2 |

| W5-3 | 360-degree gaseous discharge lamps‚ Class 3 |

| Y | Driving lamps |

| Y2 | Daytime running lamps |

| Z | Auxiliary low beam lamps |

| J590 | Turn signal flashers |

| J595 | Directional Flashing Optical Warning Devices for Authorized Emergency, Maintenance, and Service Vehicles |

| J845 | Omnidirectional Optical Warning Devices for Authorized Emergency, Maintenance, and Service Vehicles |

| J914 | Side Turn Signal Lamps for Vehicles Less than 12 m in Length |

| J945 | Vehicular Hazard Warning Flashers – Canceled July 1999 |

| J1054 | Warning Lamp Alternating Flashers |

| J1318 | Gaseous Discharge Warning Lamp For Authorized Emergency,Maintenance, And Service Vehicles |

| J1690 | Vehicular Hazard Warning Flashers |

| J2039 | Side Turn Signal Lamps for Vehicles 12 m or More in Length |

SAE PC RATING EXPLAINED

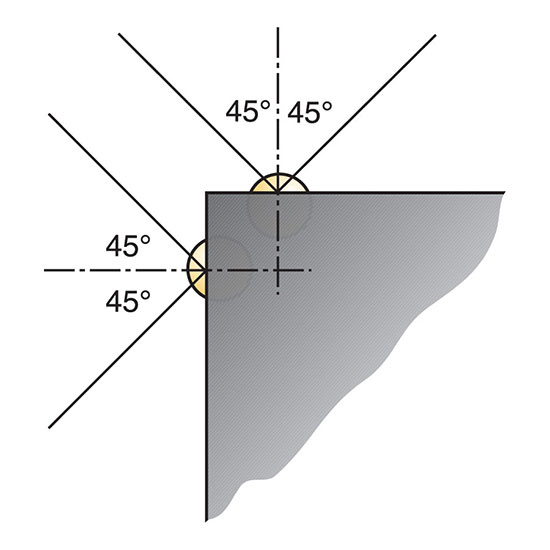

Traditional clearance and side marker lights

A traditional side marker is mounted to the side of the vehicle and is required to produce an angle of light 45° towards the front and rear of the vehicle. A traditional clearance light is mounted to the front of the vehicle or trailer and is required to produce an angle of light 45° to the left of and right of center.

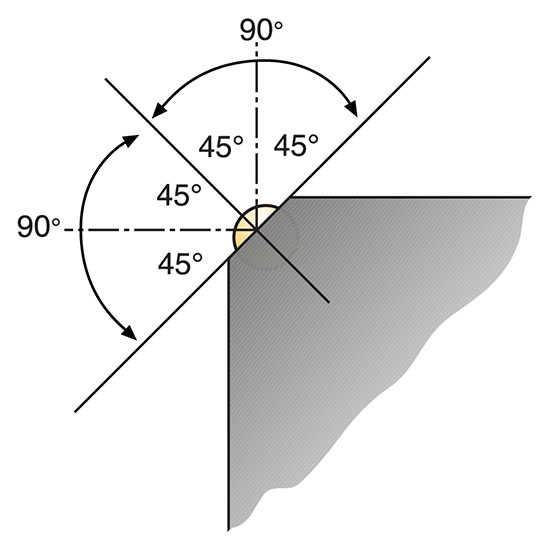

PC-Rated lights

A PC-rated lamp combines the clearance and side marker functions into one when mounted at a 45° angle at the front corner of the vehicle or trailer. It is required to produce light 90° to the left of and right of the light’s center line. PC-Rated lights save you money by combining two lights into one.

SAE CLASS RATINGS – BACK-UP ALARMS

The Society of Automotive Engineers (SAE) has developed performance standards for electric back-up alarms that are intended for use on heavy construction machinery. This chart shows the decibel level established for each of six classes defined in SAE Standard J944. The sound level tolerance for each class is +/- 4 dB(A). Alarms conforming to SAE J944 must also meet additional criteria relating to sound frequency, temperature range and resistance to rain, vibration and corrosion.

| Class | Sound Level |

| A | 112 dB(A) |

| B | 107 dB(A) |

| C | 97 dB(A) |

| D | 87 dB(A) |

| E | 77 dB(A) |

| F | Other |

SAE CLASS RATINGS – STROBES

The Society of Automotive Engineers (SAE) has developed performance standards for strobe/warning lights. This chart shows the three classes defined in various SAE standards and their intended use. Each class is defined by specific photometric criteria for flash brightness and distribution that are too complex and numerous to be listed here. Strobes conforming to SAE standards must also meet additional criteria relating to housing durability, temperature range and resistance to rain, vibration and corrosion.

| Class | Intended Function |

| 1 | Emergency Response |

| 2 | Warning |

| 3 | Identification |

American Wire Gauge (AWG) is the standard measurement of wire sizes in the US. The higher the gauge number, the thinner the conductor.

Heavier gauge wire is required as either amperage or wire length increases. Overloaded wiring can negatively affect reliability and safety due to excessive voltage drop and heat. Wires thinner than 18 AWG are not recommended for vehicular use.

The tables below provide general guidelines for choosing wire. Remember that common ground wires must be adequate to carry the total amperage on the circuit, even if separate hot wires are used.

The data included here only illustrates general wiring principles. Variables such as the exact type of wiring used and the type of devices connected will effect the actual performance of any circuit. Always verify proper operation after installation.

Wire Gauge Specification

| Gauge (AWG) | Diameter (inch) | Diameter (mm) | Cross Section (mm2) |

| 0 | 0.46 | 11.68 | 107.16 |

| 0 | 0.4096 | 10.4 | 84.97 |

| 0 | 0.3648 | 9.27 | 67.4 |

| 0 | 0.3249 | 8.25 | 53.46 |

| 1 | 0.2893 | 7.35 | 42.39 |

| 2 | 0.2576 | 6.54 | 33.61 |

| 3 | 0.2294 | 5.83 | 26.65 |

| 4 | 0.2043 | 5.19 | 21.14 |

| 5 | 0.1819 | 4.62 | 16.76 |

| 6 | 0.162 | 4.11 | 13.29 |

| 7 | 0.1443 | 3.67 | 10.55 |

| 8 | 0.1285 | 3.26 | 8.36 |

| 9 | 0.1144 | 2.91 | 6.63 |

| 10 | 0.1019 | 2.59 | 5.26 |

| 11 | 0.0907 | 2.3 | 4.17 |

| 12 | 0.0808 | 2.05 | 3.31 |

| 13 | 0.072 | 1.83 | 2.63 |

| 14 | 0.0641 | 1.63 | 2.08 |

| 15 | 0.0571 | 1.45 | 1.65 |

| 16 | 0.0508 | 1.29 | 1.31 |

| 17 | 0.0453 | 1.15 | 1.04 |

| 18 | 0.0403 | 1.02 | 0.82 |

| 20 | 0.032 | 0.81 | 0.52 |

| 22 | 0.0254 | 0.65 | 0.33 |

| 24 | 0.0201 | 0.51 | 0.2 |

Wire Gauge Required for 3% Voltage Drop at 12 Volts

| Total Circuit Amps | |||||||

| Circuit Length | 1 | 5 | 10 | 20 | 30 | 40 | 50 |

| 10’ | 18 | 16 | 14 | 12 | 10 | 8 | 8 |

| 20’ | 16 | 14 | 12 | 8 | 6 | 6 | 4 |

| 30’ | 16 | 12 | 10 | 6 | 4 | 4 | 2 |

| 40’ | 16 | 12 | 8 | 6 | 4 | 2 | 2 |

| 50’ | 16 | 10 | 8 | 4 | 2 | 2 | 1 |

| 60’ | 16 | 10 | 6 | 4 | 2 | 1 | 0 |

| 80’ | 14 | 8 | 6 | 2 | 1 | 0 | 0 |

| 100’ | 14 | 6 | 4 | 2 | 0 | 0 | 0 |

| 120’ | 14 | 6 | 4 | 1 | 0 | 0 | 0 |

Wire Gauge Required for 10% Voltage Drop at 12 Volts

| Total Circuit Amps | |||||||

| Circuit Length | 1 | 5 | 10 | 20 | 30 | 40 | 50 |

| 10’ | 24 | 18 | 18 | 16 | 14 | 14 | 12 |

| 20’ | 22 | 18 | 16 | 14 | 12 | 10 | 10 |

| 30’ | 20 | 18 | 16 | 12 | 10 | 8 | 8 |

| 40’ | 20 | 16 | 14 | 10 | 8 | 8 | 6 |

| 50’ | 18 | 16 | 12 | 10 | 6 | 6 | 2 |

| 60’ | 18 | 16 | 12 | 8 | 4 | 4 | 2 |

| 80’ | 16 | 10 | 8 | 4 | 2 | 2 | 1 |

| 100’ | 16 | 8 | 6 | 4 | 2 | 1 | 0 |

| 120’ | 14 | 8 | 6 | 2 | 1 | 0 | 0 |

INTERNATIONAL IP (Ingress Protection) RATING

| 1st Digit | Protection Level Against Solid Ingress | 2nd Digit | Protection Level Against Liquid Ingress |

| 0 | Non-protected (or not rated) | 0 | Non-protected (or not rated) |

| 1 | > 50 mm gap for entry | 1 | Vertically dripping water |

| 2 | > 12 mm gap for entry | 2 | Dripping water tilted at 15 degrees |

| 3 | > 2.5 mm gap for entry | 3 | Spraying water at an angle of 60 degrees |

| 4 | > 1.0 mm gap for entry | 4 | Splashing water at any direction |

| 5 | Dust resistant | 5 | Jets of water from any direction |

| 6 | Dust tight | 6 | Heavy seas or powerful jets of water |

| 6K | Powerful water jets with increased pressure | ||

| 7 | Harmful ingress of water when immersed to 1 meter for 30 min. | ||

| 8 | Continuous immersion in water | ||

| 9K | Powerful high temperature water jets |

Example: IP67 = [6] dust tight + [7] immersible up to 1 meter for 30 minutes

Have questions about ratings, codes, or wire gauges?

If you have any questions, please contact us.