From corrosion to splices gone bad, trailer wiring failures cost fleets serious time and money. These two wiring upgrades are helping maintenance teams simplify diagnostics, reduce downtime, and build smarter, future-ready trailers.

1. Eliminate Common Failure Points with a Fully Sealed, Modular Harness System

- ✅ Plug-and-play harnesses simplify installs and speed up repairs

- 🔧 Fewer open splices, fewer shorts, and less downtime

- 🧩 Modular design allows for quick section swaps without rewiring

If your fleet is still relying on traditional point-to-point wiring or junction boxes, it’s costing you more in the long run. Open connections and exposed wiring are especially vulnerable to corrosion, road grime, and impact damage.

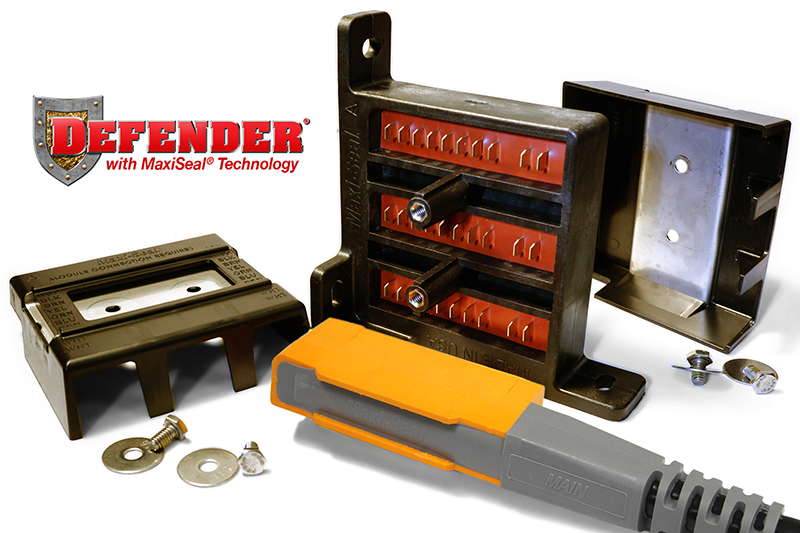

Modular harness systems, like the Defender® from Peterson, offer a fully sealed design that drastically reduces the chance of shorts, corrosion, and failure. The Defender® uses molded, corrosion-resistant plugs and includes IMB™ (Integrated Moisture Barrier) to keep moisture and debris out—extending the life of your wiring and reducing CSA violations related to lighting outages. And with a 10-Year Corrosion Warranty, it’s more than a promise—it’s proof you’re investing in uptime and long-term durability.

2. Choose Materials That Resist Corrosion and Withstand Harsh Environments

- 🌧️ Waterproof seals and grommets block out moisture and debris

- 🛡️ Tinned copper wiring resists rust and chemical damage

- 💪 Durable jacketing protects against abrasion, heat, and road wear

Even the best wiring layout can fail prematurely if exposed to corrosion. Harsh road chemicals, water intrusion, and abrasion are the leading causes of trailer wiring failure. That’s why using corrosion-resistant materials and sealed harnesses is non-negotiable for long-term fleet uptime.

Peterson’s Maxi-Seal® Harness is built with premium-grade materials, over-molded connections, and watertight seals that withstand the toughest environments—from tanker and bulk haul to off-road and municipal vehicles.

Choose a Smarter System

Peterson’s fully sealed, modular harness systems are built to handle the real-world abuse that takes down ordinary wiring. From plug-and-play installation to corrosion-resistant materials, our solutions are engineered to help fleets stay compliant, reduce downtime, and cut repair costs.

When safety and uptime matter most, trust the harness system that’s trusted by the industry.

👉 Talk to a Peterson Representative Today

Peterson Manufacturing Company

Founded in 1945, Peterson Manufacturing Company is a world-leading innovator in the design, engineering and manufacturing of a complete line of commercial vehicle/trailer safety lighting and harness systems. With headquarters in the greater Kansas City area, Peterson is a privately held company. An ISO 9001:2015 certified company, Peterson Manufacturing is a key subsidiary of Peterson Corporation, five highly specialized companies and nearly 700 associates working in global transportation-related industries. For more information, visit PMLights.com.