Trucking Costs on the Rise: FMCSA Announces 25% Fee Increase for 2025

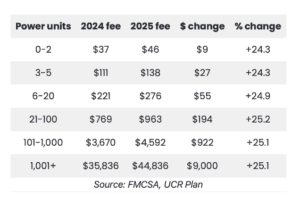

It’s a cold hard truth that just as in other areas of our lives, costs continue to keep rising. A perfect example of this is the recent raise in registration fees approved by the FMCSA that will greatly affect the trucking industry and fleets of all sizes starting in 2025. According to a posting dated Monday, June 17 in the Federal Register, there will be a 25% increase in the fees that are collected by states from motor carriers, brokers and leasing companies and used to pay for state highway safety programs. The increase will be 25% above the fees collected in 2024 and will vary “between $9 and $9,000 per entity, depending on the applicable fee bracket.”

In addition, Trucking Drive reports that the Federal Motor Carrier Safety Administration has recently announced that it has awarded $479 million in grants to states for law enforcement to conduct commercial vehicle safety inspections, investigations and audits.

With higher fees and increased inspections, now more than ever it is critical for fleets to inspect and maintain their lighting. Often times being stopped for faulty lights or other lighting violations leads to deep dive inspections for other infractions. Multiple infractions = multiple fees which can really add up and lower your bottom line.

Here are some examples of how lighting issues can cascade into other violations:

- Visibility Issues: When truck lighting is inadequate or malfunctioning (e.g., headlights, taillights, brake lights), it can affect the visibility of the vehicle. This can lead to violations related to visibility requirements, especially during nighttime or adverse weather conditions.

- Traffic Violations: Non-functioning or improperly positioned lights can lead to traffic violations such as improper lane changes, failure to signal, or failure to yield right-of-way. These violations are often cited during inspections when lighting defects are noticed.

- Safety Equipment Violations: CVSA inspections may reveal issues with other safety equipment, such as reflectors, conspicuity tape, or reflective markings. These are closely related to lighting violations as they contribute to overall vehicle visibility and safety.

- Brake System Inspections: Brake lights are critical for signaling to other drivers when a truck is slowing down or stopping. If brake lights are not functioning properly, inspectors may scrutinize the entire brake system, leading to further inspections and potential violations.

- Electrical System Deficiencies: Lighting issues can sometimes indicate broader problems with the truck’s electrical system. Inspectors may expand their checks to include electrical connections, fuses, and wiring integrity, potentially uncovering additional violations.

- Load Securement Violations: Proper lighting is essential for ensuring that loads are safely secured and visible to other drivers. If lights are obstructed or improperly placed due to cargo placement, this could lead to load securement violations.

- Documentation and Record-Keeping: Inspectors may check documentation related to the truck’s lighting maintenance and repair history. Inadequate documentation or failure to demonstrate compliance with maintenance schedules can result in violations related to record-keeping.

- Driver Hours of Service Violations: If a truck is pulled over during nighttime hours due to lighting violations, it may delay the driver’s schedule, potentially leading to violations of hours-of-service regulations if the driver exceeds allowable driving hours as a result.

- Environmental and Noise Regulations: Some jurisdictions have regulations regarding vehicle emissions and noise levels. Lighting violations that necessitate engine idling or extended inspection times could lead to inadvertent violations of these regulations.

- Driver Conduct and Behavior: Lighting violations can impact driver behavior, such as increased stress or frustration due to compromised visibility. In extreme cases, this could affect driver conduct during inspections or interactions with inspectors.

These examples illustrate how truck lighting violations can cascade into other compliance issues during CVSA inspections. Addressing lighting concerns promptly and maintaining regular inspections can help mitigate these risks and ensure overall compliance and safety on the road. For more information about how Peterson lights and wiring harness systems can help you avoid these violations, visit us at www.pmlights.com, and for technical reference guides explaining how to inspect and repair your lighting check out our maintenance guides. We’re here to help you stay on the road.

Peterson Manufacturing Company

Founded in 1945, Peterson Manufacturing Company is a world-leading innovator in the design, engineering and manufacturing of a complete line of commercial vehicle/trailer safety lighting and harness systems. With headquarters in the greater Kansas City area, Peterson is a privately held company. An ISO 9001:2015 certified company, Peterson Manufacturing is a key subsidiary of Peterson Corporation, five highly specialized companies and nearly 700 associates working in global transportation-related industries. For more information, visit PMLights.com.